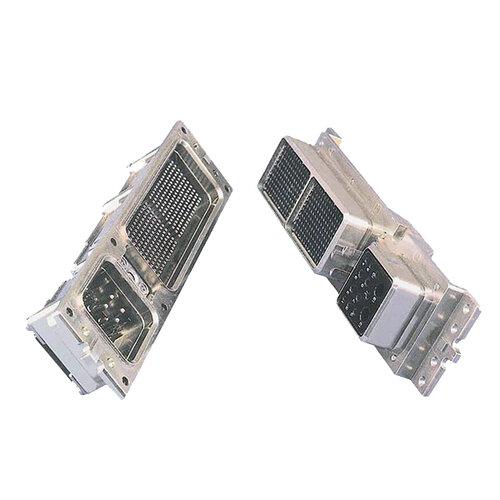

ARINC 600 Connector

ARINC 600 Connectors are a recognized standard rack and panel connector for Aircraft applications. The ARINC 600 is the successor to the ARINC 404 for many of the new avionics designs. Compared to the ARINC 404, the ARINC 600 features lower mating force contacts, increased contact count and a front release, floating keying system. Amphenol’s extensive product offering will meet the most demanding needs of our customers. At the design-in stage, Amphenol’s sales engineers will work with you to select a connector from our standard product line or coordinate the design of an application specific connector. Amphenol’s ARINC 600 rack and panel connectors are designed to meet all relevant ARINC 600 connector specifications.

TO FIND OUT MORE

Call our UK Sales team on 01494 441414

or please email us

Download the ARINC 600 Connector Product Brochure

FEATURES AND BENEFITS

Low insertion force contacts

Both environmental and non-environmental versions

Front removable keying posts

Field replaceable inserts for size 22 and power contacts

Up to 800 sizes 22 contact positions in one connector

Crimp, coaxial, power, printed circuit, and wire wrap contacts

Waveguide connections

PERFORMANCE SPECIFICATIONS

Dielectric withstanding voltage (DWV): 1500 Vrms, 500 Vms @ 50,000 ft. (15,240m)

Contact continuous current ratings:

Size 22 – 5.0A

Size 20 – 7.5A

Size 16 – 13.0A

Size 12 – 23.0A

Contact Resistance:

Size 22:8.0 milliohms, initial (max.), 11.0 milliohms, conditioned (max.)

Size 20:7.0 milliohms, initial (max.), 8.5 milliohms,conditioned (max.)

Size 16:3.5 milliohms, initial (max.), 5.0 milliohms, conditioned (max.)

Size 12:2.0 milliohms, initial (max.), 2.5 milliohms, conditioned (max.)

Insulation resistance: 5.0 gigaohms min. at 500 VDC

Engagement/separation force: Shell size 1 – 27 Ibs. (120N) max. Shell size 2 – 60 Ibs. (267N) max. Shell size 3 – 105 Ibs. (467N) max.

Durability:500 cycles min. – mating & unmating

Temperature range:-65°C (-86° F) to +125°C (+275° F)

Fluid immersion (Class A only) resistance:(1) Hydraulic fluid per MIL-H-5606

(2) Lubricating oil (synthetic) per MIL-L-23699

(3) 1:3 mix of isopropyl alcohol & mineral spirits per FED. SPECS. TT-I-735 &TT-T-291 respectively

Vibration: MIL-STD-1344, Method 2005.1, condition value E: random – 16.4G minimum severity: 8 hours in each of 3 mutually perpendicular planes with 100mA electrical load. No visible damage, breakage, cracking or loosening of parts and no discontinuities exceeding 1 microsecond.

Shock: MIL-STD-1344, Method 2004.1, test condition A: Three shocks in each direction along each of 3 axes, mutually perpendicular to each other. No visible damage, breakage, cracking or loosening of parts and no discontinuities exceeding 1 microsecond.