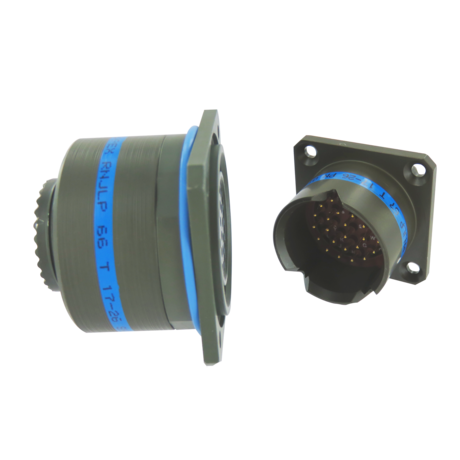

RNJLP - Rack & Panel Low Profile

Rack & Panel Connectors for harsh environments

Thanks to its high level of expertise on MIL-DTL-38999 SERIES I, II & III & EN3645 connectors, Amphenol Socapex is the industry leader in D38999 circular connectors. Offering QPL MIL-DTL-38999 and EN3645 qualified connectors with a large range of features including 38999 Rack & Panel, 38999 Miniature, 38999 Reduced Flange, 38999 Stand-off, 38999 Integrated Backshell & 38999 Power, Amphenol Socapex can answer all your needs through its line of reliable & qualitative products. Our 38999 connectors are available in Aluminum, Stainless Steel, Marine Bronze or Composite material with ROHS-compliant plating available in Black-Zinc Nickel and more. While the qualified Mil-Spec versions offer you a number of features, our customizable options are endless. We provide also free D38999 Series III CAD files.

TO FIND OUT MORE

Call our UK Sales team on 01494 441414

or please email us

PRODUCT FEATURES

Key features

Rack & Panel solutions for harsh environment

Very light weight vs ARINC 404 or 600

Derived from 38999 series III (RNJLP)

Realignment capability on 3 axis

38999 level sealing with the specific membrane mounting

Same panel distance as the ARINC 404

Applications

Battlefield Communication

Grounded vehicles

Military avionics

Technical information

Realignment capability:

Mechanical device ensures axial (+/-1mm), angular (+/-6°) and longitudinal (0.5 mm) realignments

Many insert patterns

All available Amphenol Mil-DTL-38999 III inserts

Large contacts range M39029 contacts compatible with Mil-DTL-38999 III 22D, 20, 16, 12, 8, 4 (contact cavities for signal, coaxial, twinax, power contacts)

EMI shielding

Grounding fingers ensure shielding before contact mating Low profile and high density Til 128 size 22D contacts in a 25 shell size

Shell sizes range 8 shell sizes from 11 to 25

Temperature range – 65°C to 175°C for olive drab cadmium & 200°C for electroless nickel

High durability 500 cycles minimum

High corrosion resistance

Olive drab cadmium (500 hours salt spray) or electroless nickel (48 hours salt sprayLow tooling investment

Numerous tools common with Mil-DTL-38999 series III connector ones

Light weight Aluminium alloy shells.

For the plug :

20% weight saving versus standard RNJ version

Environmental Rear membrane protected by a cap on the plug, interfacial seal on male insert

Sealing Reinforced membrane on the floating plug ensures high pressure resistance (plug withstands 1000mBars on the rear face, 2000mBars on the front face)

Rear accessory possibility

Fully compatible with all M-85049 backshells for Mil-DTL-38999 series III

Contacts protection 100% scoop proof design

Download the Product Brochure

ABOUT AMPHENOL SOCAPEX

Since 1947, Amphenol Socapex has prescribed, designed and manufactured reliable and innovative interconnection solutions for harsh environments, specializing in standard and customized electrical and fiber optic connectors, contacts, accessories and cabling solutions.

Located in the Mont Blanc region of France and Pune in India, Amphenol Socapex has a presence in over 100 countries around the world.

Amphenol Socapex is part of Amphenol Corporation.